- SURFACES

- SYSTEMS

- DOORS & DOOR PULLS

- PROJECTS

- RESOURCES

Eco-Etch Brings Houston’s Ballet Bridge to Life

| Project: | Houston Ballet Center for Dance, Pedestrian Skybridge |

| Location : | Houston, Texas |

| Year of Installation: | 2010 |

| Product Used : | Stainless steel in High-Durability Sandstone finish with custom Eco-Etch and custom Screen patterns |

| Architect: | Gensler, Houston |

| General Contractor : | W.S. Bellows Construction Corporation |

| Awards: | AIA Houston 2012 Design Award; 2012 Landmark Award for Special Projects from the Houston Business Journal; 2011 IIDA Design Excellence Award; finalist in Interior Design Magazine’s Best Projects of the Year 2011 in the Education Category |

Etched ballerinas glide effortlessly across a stunning open-air pedestrian skybridge that connects the new Houston Ballet Center for Dance and Wortham Center in downtown Houston. The bridge, diagonally spanning 130 feet, features leaping dancers on the top panels, as well as slotted perforations on the lower panels that allow for ventilation and create a unique lighting effect at night.

Gensler designed the new six-story, 115,000 sq. ft. Center, which is now the largest professional dance facility in the US. The $46 million project, completed in April 2011, was the result of collaboration with the Houston Ballet, the City of Houston, Gensler, and W.S. Bellows Construction Corporation.

Clad in black granite, the contemporary facility features large picture windows that showcase the dancers as they work in their rehearsal studios. It also provides a beautiful new addition to Houston’s renowned Theater District.

Reaching Skyward

The skybridge, fast becoming an iconic Houston landmark, allows dancers, students, staff, and wardrobe to travel directly from the new building to Wortham Theater Center's back stage.

According to Terry Newell, an architect at Gensler, several schemes for the bridge were reviewed, including an L-shape across two streets. The diagonal scheme was chosen because it used fewer materials, had preferred termination points, and more visual appeal. The open-air pedestrian bridge was funded by Main Street TIRZ with a budget of $1.5 million.

Inspired by Dance

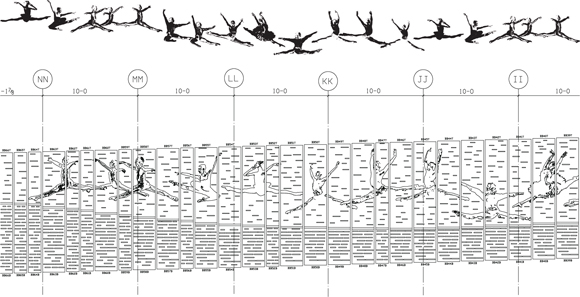

Top: Artwork of dancers, created from photos of actual troupe members, provided to Forms+Surfaces by Gensler. Bottom: Section of Forms+Surfaces’ Eco-Etch drawings created from the artwork provided by Gensler.

A key aspect of the bridge was that it had to continue the theme of “a billboard for dance,” which is reflected in the Center’s overall design.

Newell said, “As seen in the whole project, the bridge design features a geometry of panels with varying widths and lengths that give it a rhythmic quality.”

Additionally, the concept included etched silhouettes of dancers. When the architects at Gensler saw Forms+Surfaces Eco-Etch stainless steel, they realized the product was an ideal fit for the project.

Our Eco-Etch process creates beautiful etched designs that are applied using an advanced photolithographic bead-blasting system instead of using acids or other harmful chemicals. Eco-Etch allows for a wealth of design possibilities with artwork supplied by the specifier or developed by Forms+Surfaces. The process is non-invasive to the stainless steel, and non-porous, which minimizes dirt collection—factors that add to the inherent benefits Eco-Etch.

In this case, actual troupe members from the ballet were photographed while dancing. Gensler designers composed the group of dancers into a continuous line that spanned the street to create the digital images that were Eco-Etched on to the panels.

Newell said that using photos of the real dancers was an important way to brand the project. “In a way, it has immortalized these dancers as a permanent part of the downtown Houston cityscape,” he said.

The Perfect Perforations

Another important design feature of the bridge was custom Screen pattern created with rectangular perforations. Newell explained that the lower panels were perforated for several reasons. First of all, a linear pattern inspired by the Benesh system of dance notation (similar to written music) is repeated in several elements of the Center for Dance design, including the window frit pattern, lighting, and even the carpet. The perforations tie back to this motif.

The bridge was also designed as an open-air structure to reduce costs, so the perforations allow air circulation.

At night, the perforations allow drivers and pedestrians below to catch glimpses of the costumed dancers crossing the bridge between rehearsal and performance venues.

Bridging the Gap

There were some structural challenges to creating the bridge. Because an extensive amount of steel was required to clear the intersection at the desired height, the budget for cladding had to be reduced.

Additionally, Forms+Surfaces had to design the panels to withstand 150 mph winds at a height of 60 feet. When it was determined that additional brackets and supports for the structure would be needed, cost estimates rose and the City began looking for other alternatives.

Fortunately, the architects at Gensler chose our product to help bring their iconic design to life. Although they mocked up some alternative materials, our non-directional Sandstone finish, the Eco-Etching, and the crisp perforations were key criteria in their decision.

The Final Performance

Ultimately, the City of Houston and the Ballet’s donors raised the additional funds to ensure that the bridge would feature Eco-Etch stainless steel.

“Our capabilities were far beyond what the competition could do,” said Forms+Surfaces Regional Sales Manager John Wafford, “and that fit Gensler’s vision as well.”

That vision meant that everything had to be very refined – all of the panel edges needed to be completely smooth and polished, and there could be no weld marks.

Fortunately, Forms+Surfaces was up to the task, providing 3,800 sq. ft. of stainless steel with custom Screen perforations and Eco-Etch designs, as well as the support brackets.

.jpg)

A Standing Ovation

C.C. Conner, Managing Director Emeritus for the Houston Ballet said, “Forms+Surfaces provided not only a superior product but also professionally designed shop drawings which helped us visualize and select the designs used.”

“They had a start-to-finish commitment from sales to engineering, were great partners, and exceeded our expectations.”

Public reactions to the bridge have also been stellar.

Steven Thomson, writer for Culture Map Houston, wrote in his review of the Center, “Perhaps the building’s most dynamic feature is the bridge.”

And, in an article in the Houston Chronicle listing things Houston has to be thankful for at year’s end of 2010, it listed, “…the sexy, shimmering skybridge that connects the new Houston Ballet building to Wortham Center.”

Forms+Surfaces is very proud to have been involved in this landmark project. If you are working on a project and are interested in our Eco-Etch capabilities, Screen patterns, stainless steel, or any of our other surfaces, visit www.forms-surfaces.com to learn more.

LinkedIn Pinterest Instagram Facebook YouTube Vimeo